vickers hardness test astm pdf|astm e92 pdf free download : fabrication 1. Scope. 1.1 This test method covers the determination of the Vickers hardness of metallic materials, using applied forces of 1 kgf to 120 kgf,2 the verification of Vickers hardness . WEB13 de mai. de 2020 · IDOV (Identify, Design, Optimize and Validate) is a step-by-step approach to Six Sigma as applied to product and service design. The four basic steps of .

{plog:ftitle_list}

web18 de fev. de 2024 · Baixe Instagram MOD APK 2023 Curtidas ilimitadas, seguidores versão mais recente e desfrute de uma experiência imersiva de mod. Baixar gratuitamente Instagram v320.0.0.0.7 MOD APK em Moddroid.com!

1. Scope. 1.1 This test method covers the determination of the Vickers hardness of metallic materials, using applied forces of 1 kgf to 120 kgf,2 the verification of Vickers hardness .

E691 Practice for Conducting an Interlaboratory Study to 3.2.2 microindentation hardness test, n—a hardness test, Determine the Precision of a Test Method 3 normally in the Vickers or Knoop scales, using test forces in 2.2 ISO .The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .perform macro Vickers hardness tests as previously defined in Test Method E92, Standard Test Method for Vickers Hardness Testing. 1.4 This test method includes an analysis of the .Vickers and Knoop hardness test principle: An indentation hardness test using a verified machine to force an indenter, under specified conditions, into the surface of the material under .

1.4 This test method covers Vickers hardness tests made utilizing test forces ranging from 9.807 × 10 -3 N to 1176.80 N (1 gf to 120 kgf), and Knoop hardness tests made .Standard Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials 1. Andy Delgado. This standard is issued under the fixed designation E92; the number immediately following the designation indicates the year of .

vickers hardness test procedure pdf

1.1 This test method covers determination of the Knoop and Vickers hardness of materials, the verification of Knoop and Vickers hardness testing machines, and the calibration of .standard provides the requirements for Vickers and Knoop defined in terms of the test force in kilogram-force (kgf) and the surface. hardness machines and the procedures for performing Vickers area or projected area in millimetres .1.4 This test method covers Vickers hardness tests made utilizing test forces ranging from 9.807 × 10-3N to 1176.80 N. (1 gf to 120 kgf), and Knoop hardness tests made utilizing test forces .

Vickers hardness of materials, the verification of Knoop and Vickers hardness testing machines, and the calibration of standardized Knoop and Vickers test blocks. 1.2 This test method covers Knoop and Vickers hardness tests made utilizing test forces in micro (9.807 3 10-3 to 9.807 N)(1to1000 gf ) and macro (>9.807 to 1176.80 N) ( >1kghigher. At lower test loads the Vickers hardness may be load-dependent. In Table 2 are given the Vickers hardness numbers for a test load of 1 kgf. For obtaining hardness numbers when other test loads are used, the Vickers hardness number obtained from Table 2 is multiplied by the test load in kilograms-force (Table 3). N. ote Note 1: The Vickers and Knoop hardness numbers were originally defined in terms of the test force in kilogram-force (kgf) and the surface area or projected area in millimetres squared (mm 2).Today, the hardness numbers are internationally defined in terms of SI units, that is, the test force in Newtons (N). However, in practice, the most commonly used force .ISO 6507-1, Metallic materials — Vickers hardness test — Part 1: Test method ISO 6507-3, Metallic materials — Vickers hardness test — Part 3: Calibration of reference blocks 3 Terms and definitions No terms and definitions are listed in this document. ISO and IEC maintain terminological databases for use in standardization at the .

ASTM E92-17 Standard Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials - Free download as PDF File (.pdf), Text File (.txt) or read online for free.

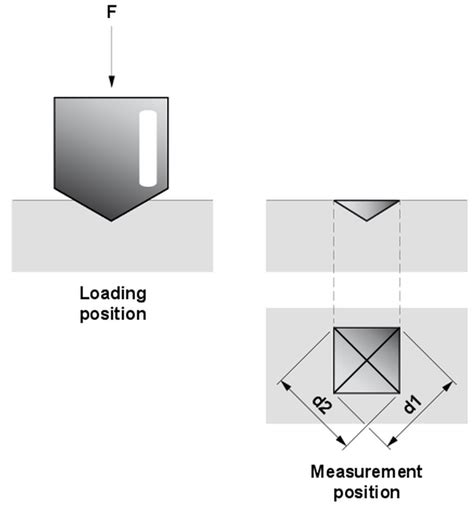

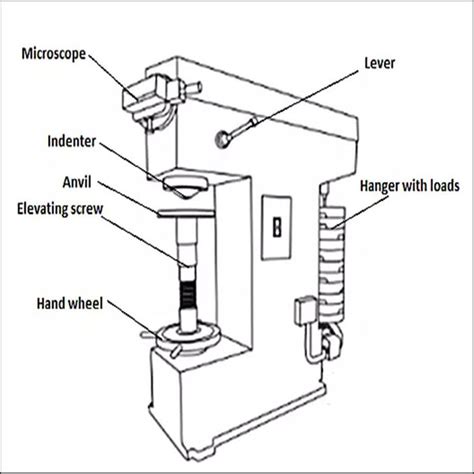

A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter . Standard Test Method for Knoop and Vickers Hardness of Materials E0384-11 ASTM . ASTM grants Licensee a limited, revocable, nonexclusive, non-transferable license to access, by means of one or more authorized IP addresses, and according to the terms of this Agreement, to make the uses permitted and described below, each ASTM Product to which .Step 2 - For the Vickers hardness test, the lengths of the two diagonals are measured and the mean diagonal length is calculated, which is used to derive the Vickers hardness . found in Test Method ASTM E384. Sample surface preparation: For optimum accuracy of measurement, the test should be performed on a flat specimen with a polished or .Note 1: The Vickers and Knoop hardness numbers were originally defined in terms of the test force in kilogram-force (kgf) and the surface area or projected area in millimetres squared (mm 2).Today, the hardness numbers are internationally defined in terms of SI units, that is, the test force in Newtons (N). However, in practice, the most commonly used force units are kilogram .

Vickers hardness of materials, the veriÞcation of Knoop and Vickers hardness testing machines, and the calibration of standardized Knoop and Vickers test blocks. 1.2 This test method covers Knoop and Vickers hardness tests made utilizing test forces in micro (9.807 3 10-3 to 9.807 N)(1to 1000 gf ) and macro (>9.807 to 1176.68 N) ( >1 to 120 .Brinell Hardness The Vickers hardness test utilizes a pyramidal diamond in-denter to create an indentation on the material‘s surface. The diagonals (x and y axis) of the indentation are measured, and . DIN EN ISO 6506 / ASTM E10 Brinell Methods 2.2 Method Indenter Load F kg Load F N Load Factor 0.102 x F/D2 Hardness Range HBW* Material

ASTM Test Methods E691 Practice for Conducting an Interlaboratory Study to . Standard Test Method for Vickers Hardness Testing of Metallic Material that was under the jurisdiction of E28.06 Current edition approved Oct. 1, 2022. Published November 2022. Originally approved in 1969. Last previous edition approved in 2017 as E384 Ð 17.Displays test conditions and test results. By entering the specimen thickness and the presumed hardness, you can set a test force that satisfies the JIS conditions. Used for selecting a conversion scale, entering a setting for Pass/Fail determination, and specifying external output. In addition to the test force dwell time, you can specify Mechanical hardness testing is fundamental in the evaluation of the mechanical properties of metallic materials due to the fact that the hardness values allow one to determine the wear resistance .Tracked Changes. Metallic Materials. Vickers Hardness Test British Standards Institution,2020 . PDF, MOBI, and More Astm E92 Standard Test Methods For Vickers Hardness Compatibility with Devices Astm E92 Standard Test Methods For Vickers Hardness Enhanced eBook Features 7. Enhancing Your Reading Experience

Standard Test Method for Knoop and Vickers Hardness of Materials E0384-11E01 ASTM|E0384-11E01|en-US Standard Test Method for Knoop and Vickers Hardness of Materials Standard E384 Standard Test Method for Knoop and Vickers Hardness of Materials > new BOS Vol. 03.01 Committee E04 $ 129.00 In stock

3.1.1 Vickers hardness number (HV), n—an expression of hardness obtained by dividing the force applied to a Vickers indenter by the surface area of the permanent impression made by the indenter. 3.1.2 Vickers indenter, n—a square-based pyramidal-shaped diamond indenter with face angles of 136° 008. 4. Summary of Test Method 4.1 This test . Download file PDF Read file. Download file PDF. Read file. Download citation. Copy link Link copied. . Aim: To determine the hardness of the given Specimen using Vickers hardness test.

Using guidelines for ASTM E-384/92 Vickers hardness testers standards, the 3842 digital Vickers hardness tester will offer unmatched repeatability. A perfect rugged performer . The advantages of the Vickers hardness test are that extremely accurate readings can be taken, and just one type of indenter is used for all types of metals and .JIS R 1610 Testing Method for Vickers Hardness of High Performance Ceramics5 2.4 ISO Standard: ISO 6507/2 Metallic Materials—Hardness test—Vickers test—Part 2: HV0.2 to less than HV5 6 3. Terminology 3.1 Definition: 3.1.1 Vickers hardness number (HV), n—an expression of hardness obtained by dividing the force applied to a Vickers

5.3 Because microindentation hardness tests will reveal hardness variations that commonly exist within most materials, a single test value may not be representative of the bulk hardness. Vickers tests at 1000 gf can be utilized for determination of the bulk hardness, but, as for any hardness test, it is recommended that a number of indents are made and the average .

ASTM E92-17 Standard Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials. . 1.4 This test method covers Vickers hardness tests made utilizing test forces ranging from 9.807 × 10-3 N to 1176.80 N . Documents sold on the ANSI store are in electronic Adobe Acrobat PDF format , however some ISO and IEC standards are .

Note 1: The Vickers and Knoop hardness numbers were originally defined in terms of the test force in kilogram-force (kgf) and the surface area or projected area in millimetres squared (mm 2).Today, the hardness numbers are internationally defined in terms of SI units, that is, the test force in Newtons (N). However, in practice, the most commonly used force . 1.3 Conversion Table 3 presents data on the relationship among Brinell hardness, Vickers hardness, Rockwell hardness, Rockwell superficial hardness, and Knoop hardness of nickel and high-nickel alloys (nickel content over 50 %). These hardness conversion relationships are intended to apply particularly to the following: nickel-aluminum-silicon specimens finished .Vickers hardness testing to ASTM E92 is a hardness test method with optical evaluation in which the size of the indentation left on the surface of the test material by a pyramid-shaped diamond indenter (square base and interfacial angle of α = 136°) is measured. The test load is applied precisely and the diagonals of the indentations are used to calculate the Vickers .following are the most common hardness test methods used in today`s technology: 1. Rockwell Hardness test 2. Brinell Hardness 3. Vickers Hardness 4. Knoop Hardness 3.1: Rockwell Hardness Test The Rockwell Hardness test is a hardness measurement based on the net increase in depth of impression as a load is applied.

1.1 Conversion presents data in the Rockwell C hardness range on the relationship among Brinell hardness, Vickers hardness, Rockwell hardness, Rockwell superficial hardness, Knoop hardness, and Scleroscope hardness of non-austenitic steels including carbon, alloy, and tool steels in the as-forged, annealed, normalized, and quenched .

vickers hardness test manual

web1º PRÊMIO. PIX DE 4 MIL REAIS. Sugestao de uso do premio no valor liquido total de R$ 4.000,00. 14. 26. 07. 03. 39. 22. 01. 33. 38. 08. 02. 36. 21. 11. 30. 40. 16. 27. 35. 12. 31. .

vickers hardness test astm pdf|astm e92 pdf free download